Do you want to use stickers to elevate your product packaging, but are not sure how to find the perfect material? Or would you simply like to know what your options are to ensure you can deliver the best possible quality to your customers?

Then you have come to the right place. In this article, we will give you step-by-step tips on how to find the right sticker material for your business. All of these tips revolve around custom stickers which give you ultimate flexibility when it comes to choosing your design, size, quantity and material.

So, without further ado, let us jump into the world of sticker materials.

1. Paper or vinyl?

The decision between paper or vinyl-based stickers is the most basic material question you need to answer. Custom vinyl stickers, like you can find right here, are perfect for indoor and outdoor uses. They are resistant to scratches, water and sunlight and will stick to almost all surfaces.

Paper stickers are equally sticky, but tend to be less resistant. However, as they are made from wood-free paper, they are completely plastic-free, which is great for the environment. While vinyl and paper stickers can usually be used for similar applications, it can be worth ordering some material samples to decide which one would work best for you.

2. Find your perfect look

Once you know which basic material you are after, you can then think about the look your sticker should have. This largely depends on the surface you will apply your stickers to. You can opt for non-see through stickers or a transparent material to create clear labels.

Non-see through stickers are usually referred to as white stickers. This does not mean that you will be stuck with a white color. Instead, any color can be printed over the white base, giving you an opaque finish.

Transparent materials, on the other hand, are perfect for applications to glass-based or any other see-through surfaces as they allow your customers to see that surface through your sticker. If you would like to print color on top of the transparent material without using a white base, you can create a beautiful stained-glass effect.

3. Think of your brand values

Your product packaging is much more than a logo sticker. It can be used to communicate specific features or values that are characteristic of your business.

Do you specialize in luxurious, high-quality products? Then you can use a vinyl-based effect material to share that with your customers. A glitter or holographic label creates a beautiful metallic look and adds the perfect premium finish to your product.

Or maybe, your brand is all about sustainability? You can still get the perfect stickers by opting for a biodegradable paper sticker or choosing a bio-plastic made from wood pulp. All of these stickers will decompose within 12 weeks and can help you share your ethics with your customers.

4. Make them practical

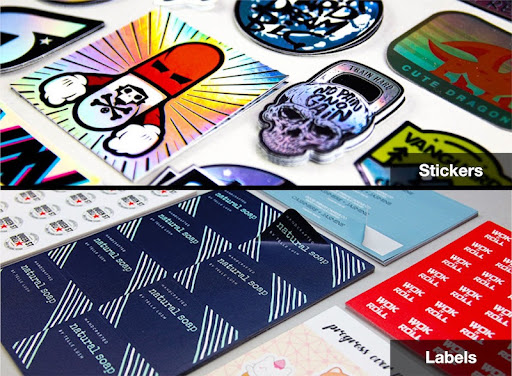

There is one more decision to make. Most sticker printers offer individually cut stickers as well as labels. There is no inherent difference between the two: materials, designs and sizes will be the same. However, labels usually arrive on sheets and are not individually cut.

If you have to apply hundreds of stickers to your products or shipping boxes, it can be worth investing in labels. Labels can be 65% faster to apply, saving you valuable time. As they arrive on sheets, they are easy to store and keep organized as well.

We hope these tips will help you find your perfect sticker material in no time. If you would like to share your advice or experience, or have any questions, please leave us a comment in the section below.